The oil and gas industry operates in complex environments where efficiency, safety, and environmental compliance are paramount. Filtration and purification processes are crucial in ensuring that crude oil, natural gas, and refined products meet regulatory and operational standards. With increasing global energy demands and stricter environmental laws, adopting advanced filtration technologies has become more critical than ever.

The Need for Purification & Filtration

Oil and gas extraction, transportation, and refining involve multiple contaminants that can negatively impact efficiency and safety. These include:

Particulates: Sand, dust, and rust that cause wear on machinery and pipelines.

Water and Moisture: Leads to corrosion, degradation of fuels, and equipment malfunctions.

Sulfur and Other Chemicals: Contribute to pollution and must be removed to meet regulatory standards.

Heavy Metals: Harmful to both equipment and the environment, requiring specialized removal methods.

Cutting-Edge Filtration Technologies

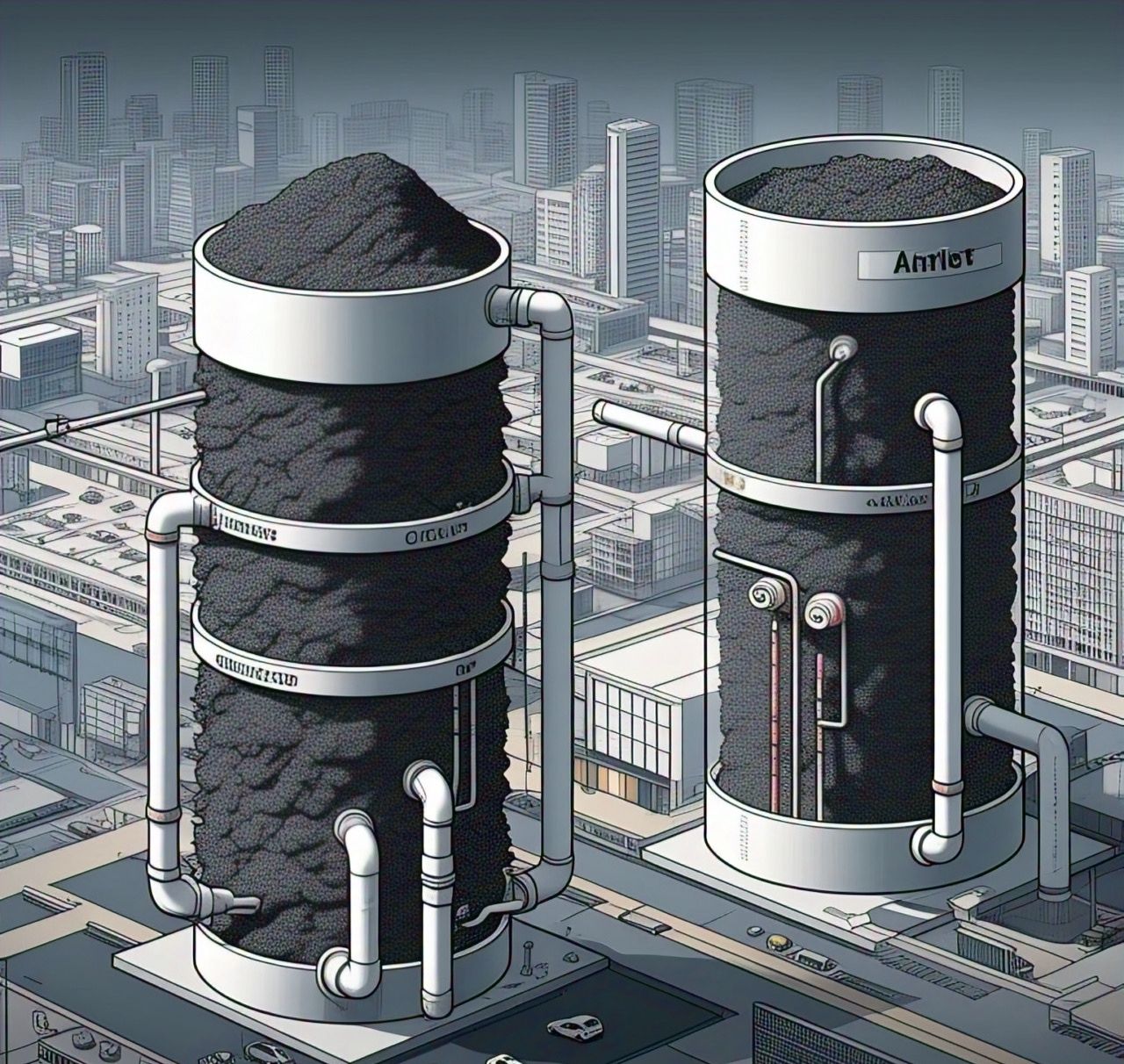

To combat contamination challenges, the industry employs a variety of filtration and purification systems, including:

Depth Filtration: Uses layered materials to trap fine particles and improve fluid purity.

Coalescers: Separate oil, water, and gas to prevent corrosion and enhance fuel efficiency.

Electrostatic Precipitators: Utilize electrical charges to remove ultra-fine contaminants from gas streams.

Ceramic Membranes: Offer high-temperature and high-pressure resistance for efficient purification.

Hydrocyclones: Centrifugal force technology to separate solids and liquids efficiently.

Emerging Trends in Oil & Gas Filtration

As technology evolves, so do purification and filtration methods. Some of the latest innovations include:

AI and IoT-Based Monitoring: Smart sensors and predictive analytics help optimize filtration processes in real time.

Nanotechnology Filters: These offer superior contaminant removal while reducing energy consumption.

Eco-Friendly Filter Materials: The industry is shifting toward sustainable, biodegradable filtration materials to reduce environmental impact.

Advantages of Effective Filtration

Investing in high-performance purification and filtration solutions provides numerous benefits:

Enhanced Equipment Performance: Reduces wear and tear, extending operational life.

Improved Product Quality: Ensures fuels and lubricants meet industry and environmental standards.

Regulatory Compliance: Helps companies meet strict pollution control and safety regulations.

Cost Efficiency: Minimizes maintenance and downtime, leading to significant savings.

Environmental Sustainability: Reduces emissions and waste, contributing to a cleaner planet.

Key Filtration & Purification Technologies

To address these challenges, the oil and gas sector utilizes a range of purification and filtration technologies:

Centrifugal Separators: Used to remove solids and water from crude oil and natural gas streams.

Activated Carbon Filters: Essential for eliminating organic impurities and sulfur compounds.

Coalescing Filters: Help in separating water and oil phases to prevent corrosion and improve fuel quality.

Membrane Filtration: Advanced membranes aid in the separation of gases and liquids, improving purity levels.

Electrostatic Filters: These use electrical fields to capture fine particles and contaminants.

Future Trends in Oil & Gas Filtration

The industry is rapidly evolving with new filtration innovations that improve efficiency and sustainability. Key trends include:

Smart Filtration Systems: AI-powered monitoring optimizes filter performance in real-time.

Nanotechnology Filters: Ultra-fine filtration capabilities for better contaminant removal.

Sustainable Filtration Materials: Development of biodegradable and recyclable filter components.

Conclusion

Filtration and purification are indispensable in the oil and gas sector, ensuring operational efficiency, regulatory compliance, and environmental responsibility. As technology advances, companies must embrace modern filtration solutions to stay competitive and sustainable in a rapidly changing industry.

By prioritizing advanced purification and filtration technologies, the oil and gas industry can enhance productivity, safeguard resources, and contribute to a more sustainable energy future.